for precision optics, photonics & semiconductor applications

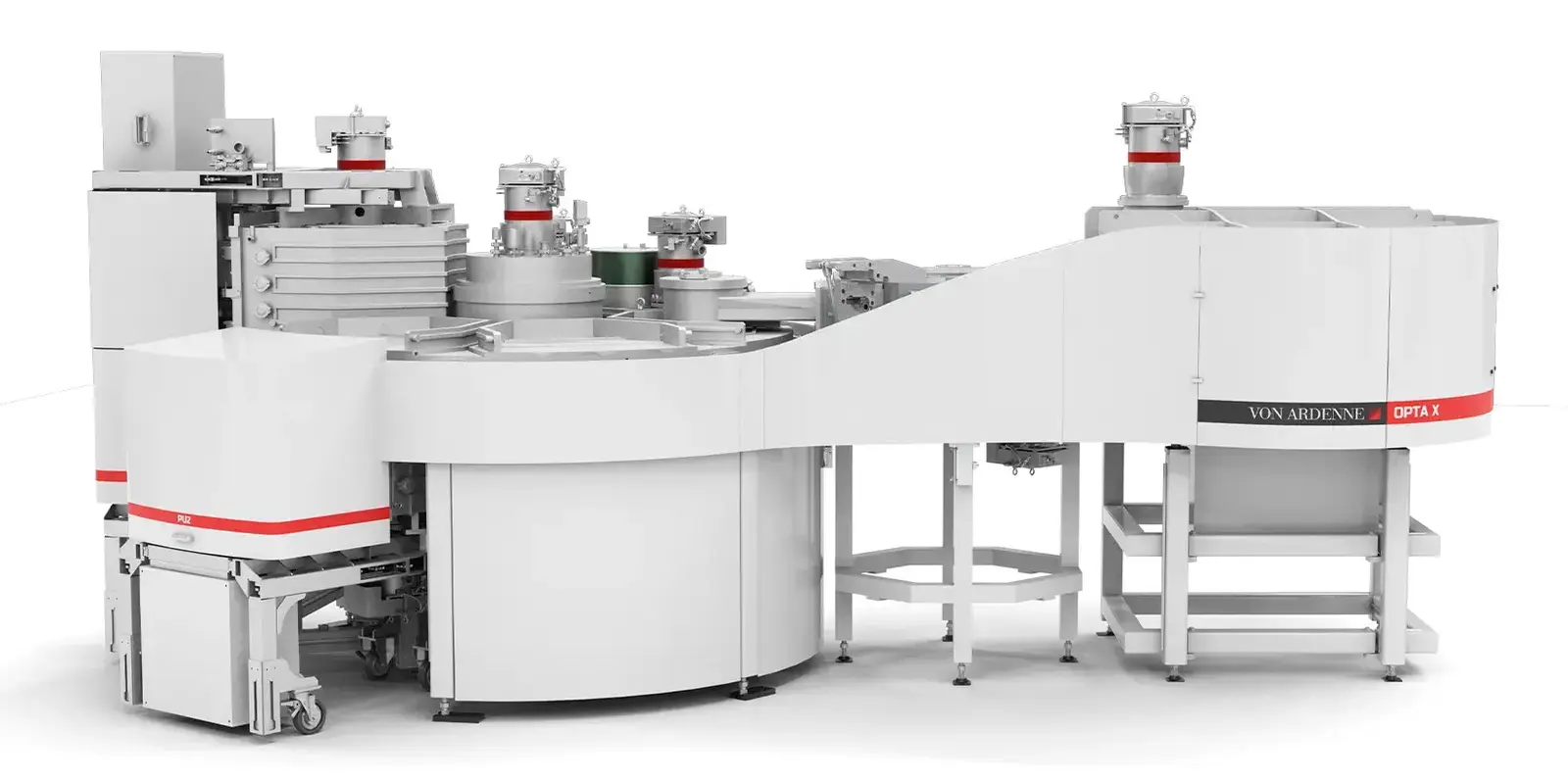

- Manufacturing of vacuum coating systems

- Sampling & pilot deposition services

- 600 m² semiconductor cleanroom including AMC capability

Engineering

Simulation . Sampling . Layout

Technology & Application Center

Sampling . Development . Scaling

Service

Customer Portal . Spare Parts . Trainings

San Francisco, CA, USA

The Moscone Center

Booth 2261

Shanghai, China

Shanghai New International Expo Center

N1 / 181

Shanghai, China

National Exhibition and Convention Center

A006

San Francisco, CA, USA

Moscone Center

North Hall | Booth 5373

Munich, Germany

Exhibition Center

C2 / C2317

Vice President Semiconductors & Precision Optics I Space & AviationVON ARDENNE GmbH