Thermal evaporation of aluminum using ceramic boats is one of the most established methods in thin-film technology – particularly in the production of barrier films for packaging applications. A typical boat evaporator consists of multiple ceramic evaporation units, an evaporator box with an observation flap, and individually controlled power supplies. The number of evaporators that are used depends on the size of the system and the desired throughput.

How the Technology Works

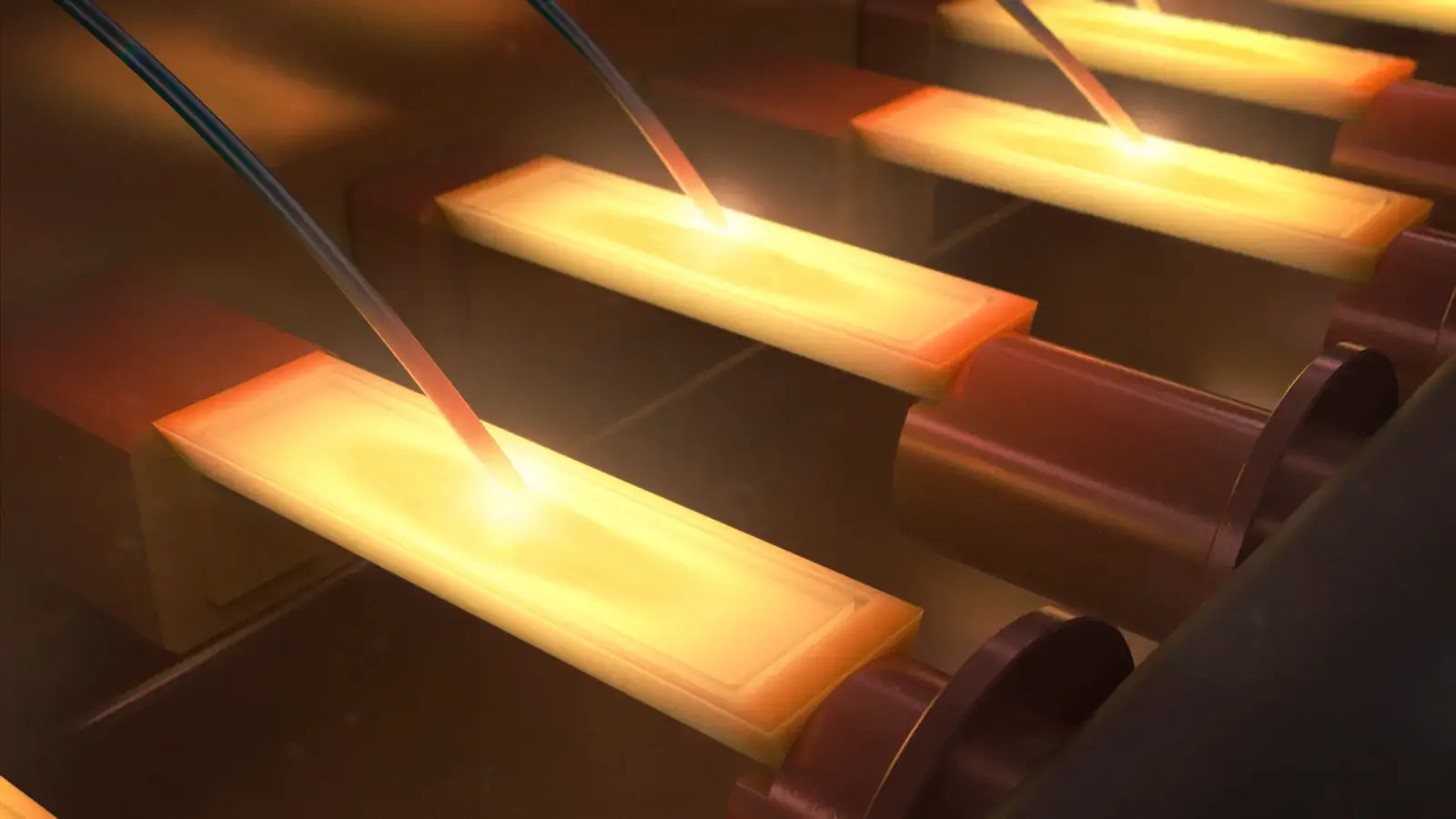

The ceramic boats, typically made from boron nitride or aluminum oxide, serve a dual function: they act as both the carrier of the aluminum and the heating element. Aluminum wire is fed into a cavity on the top side of each boat. Once electrical current is applied, the boat heats resistively to over 1500 °C, causing the aluminum to melt and evaporate.

The process takes place under high-vacuum conditions (typically around 10⁻⁴ mbar) to ensure a clean, uniform aluminum deposition on the moving substrate – such as PET or BOPP film – without unwanted chemical reactions or contamination.

Multi-Boat Evaporators for Industrial Coating

Modern roll-to-roll coating systems use what are known as multi-boat evaporators, in which several ceramic boats are arranged linearly and evenly spaced. To further optimize layer uniformity across the web, the boats are often arranged in a staggered formation. This configuration minimizes overlapping of aluminum vapor clouds and ensures a particularly homogeneous, dense, and visually high-quality coating.

Material Flexibility and Process Variants

In addition to aluminum, copper can also be evaporated under suitable process conditions. However, the achievable deposition rates and process window are more limited. By introducing a controlled amount of oxygen into the evaporation zone, aluminum oxide can be generated directly during the process. This enables the production of a cost-effective, transparent barrier layer, which is becoming increasingly important in the packaging industry.

Our Expertise – Your Advantage

Boat evaporators are one of the core technologies of the VON ARDENNE Group. We develop and manufacture these systems entirely in-house – including all associated technologies. The solutions we provide are based on extensive practical experience from numerous systems delivered worldwide.

Would you like to learn more? Then click on the content below or contact us directly.