Measurement Systems

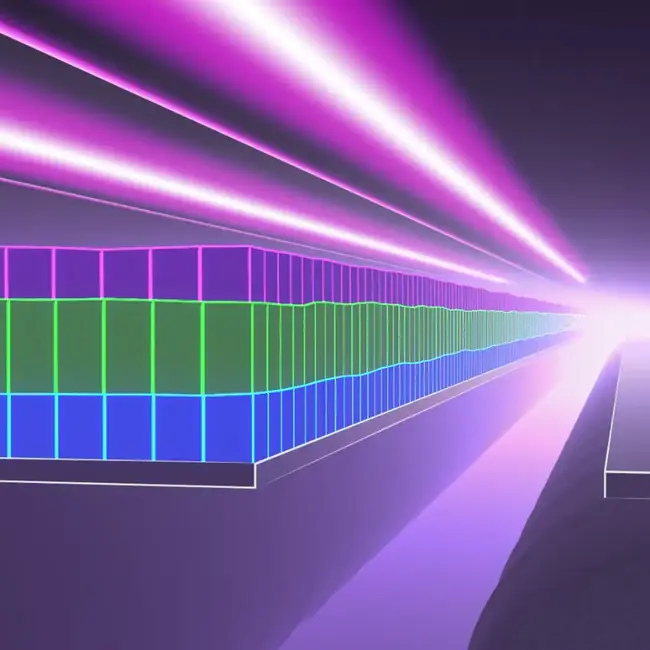

during vacuum coating

The continuous verification of the coating properties in the coating process is an important task when you operate a coating system. This concerns quality assurance as well as defect detection and parameter control. Important measured variables here are optical properties such as reflection and transmission. But sheet resistance is also decisive.

VON ARDENNE offers two solutions here. The in-situ measurement system consists of locally fixed measuring heads in the line after each coating step. They provide information on the respective individual coating in one track. The ex-situ measurement system scans the entire surface of the coated product after it has left the line.

With the information from both systems, you can measure the properties and their distribution for quality assurance. And you can draw conclusions about the control of the process parameters of each individual layer.

Do you want to learn more? Then click on the individual components or contact us directly.

Would you like to know more? Then click on the individual components or contact us directly.

Engineering

Simulation . Sampling . Layout

Technology & Application Center

Sampling . Development . Scaling

Service

Customer Portal . Spare Parts . Trainings

Boston, MA, USA

Phoenix, AZ, USA

Phoenix Convention Center

Booth 6180

Dresden, Germany

International Congress Center

Booth F3

Hamburg, Germany

Exhibition Center Hamburg

B7 / 7C71

Greater Noida, India

India Expo Center

German Pavillon